The bulk of the manufacturing work that Evaero does involves CNC precision machining of complex metal parts. The aerospace and defense industry has increasingly become commoditized, and I find our buyers and decision-makers, while they know what they need, don’t totally understand what we do. For that reason, I thought it might be worthwhile to take a little time to introduce you to machining. First, a definition:

The bulk of the manufacturing work that Evaero does involves CNC precision machining of complex metal parts. The aerospace and defense industry has increasingly become commoditized, and I find our buyers and decision-makers, while they know what they need, don’t totally understand what we do. For that reason, I thought it might be worthwhile to take a little time to introduce you to machining. First, a definition:

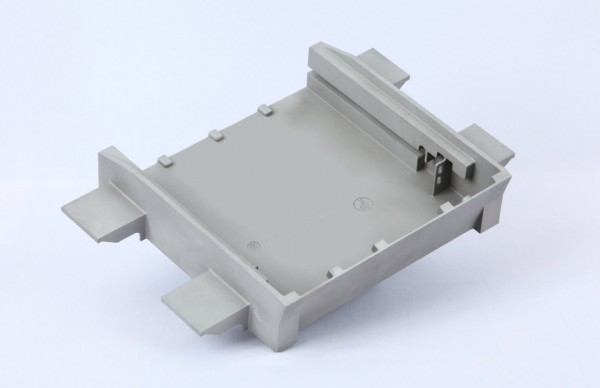

Machining is a manufacturing process that adds value to a generic or near net shape by removing material from that shape in a controlled manner.

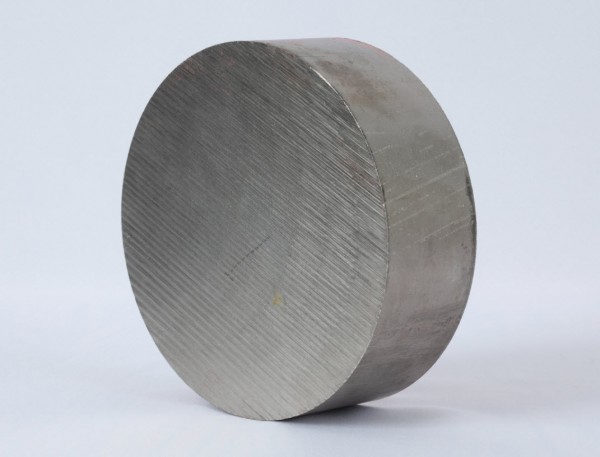

The parts we machine are mostly made from alloys based on aluminum, titanium, or steel. As a generic form, these materials come to us as bars or blanks; as a near net shape, they come to us as castings. Although I’ll talk more about castings in a future post, for now I’ll just say a large portion of the parts we make start off as investment castings.

There are many ways one can remove metal to create a finished product. At Evaero, we “cut” metal away using computer controlled (i.e., CNC) equipment broadly classified as “machine tools.”

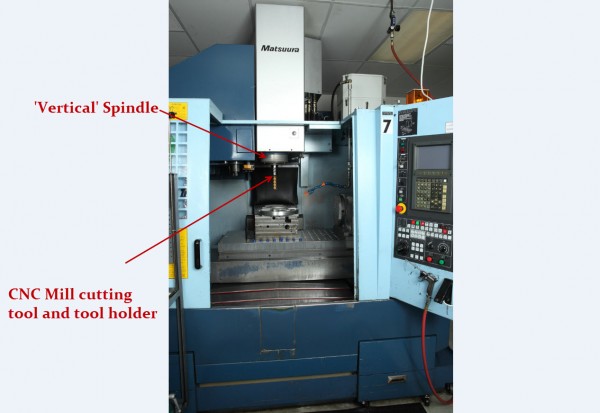

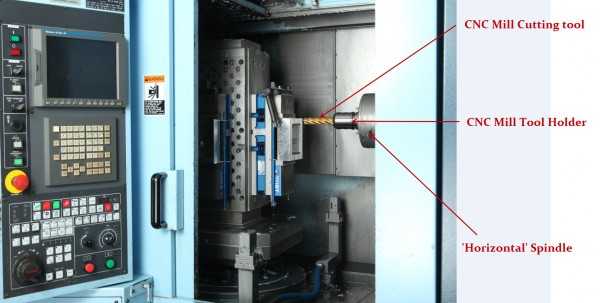

Two types of machine tools are often used to do the cutting work:

- Milling centers typically cut metal by spinning cutting tools, held in a vertically or horizontally oriented spindle with a tool holder, against a secured stationary piece of material.

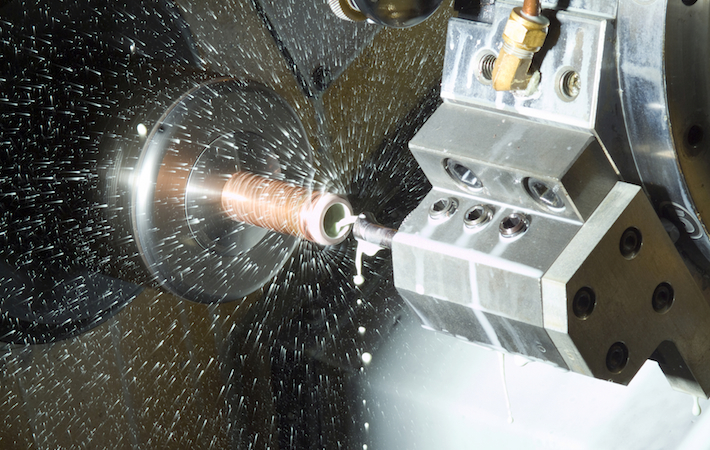

- Turning centers are used to make round parts. The material is typically spun in the spindle rather than the cutting tool as in milling centers.

Although the machine tools themselves receive most of the attention on factory tours, the cutting tools used to remove the metal are just as, if not more, important than the machines driving them. Cutting tools come in all different shapes and geometries, are made of different types of materials, and are often coated to prolong tool life.

Due to the staggering number of tooling options available, many manufacturing companies outsource the management of their cutting tools. At Evaero, we view this to be a core competency that has profound implications on cost and quality and too important to outsource. Not only have we developed, and subsequently manage, our own tooling system, but we also employ an in-house tooling expert to make these key decisions.

Machining, more specifically CNC precision machining, is a “subtractive” manufacturing process that uses machine tools and cutting tools to produce finished components from generic or near net shapes. One might view subtractive processes as wasteful because of all the metal that is cut away, however, we recycle the bulk of the scrap metal to metal recyclers as far away as New York and very little is in fact wasted. That distinction made, with all the increased attention being paid to “additive” processes such as 3D printing, in a future post we will discuss how additive processes are likely to impact the future of machining.

— xian

Figures 1-7 photo credit: Kenneth Stuck (Evaero)